EEN OFFERTE AANVRAGEN

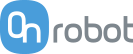

GECKO GRIPPER

COMPACTE HECHTENDE GECKO GRIPPER DIE GEEN MARKERINGEN ACHTERLAAT

- Compact, lightweight Gecko Gripper requires no cables, electricity, air, or programming for cost-effective, plug-and-play performance

- Innovative adhesive gripper for flat, smooth, or perforated objects automates tasks that were never possible before

- Gripper technology that leaves no markings for glossy surfaces – no cleaning required, saving you time and improving productivity

Waarom de Gecko Gripper?

The Gecko Gripper brings the innovative adhesive Gecko gripper technology to applications with a small footprint that were previously impossible to automate. The Gecko-inspired adhesion technology provides precise gripper technology that leaves no marks, even for perforated objects such as printed circuit boards or for glossy surfaces, without the cleaning process. The three different Gecko grippers (SP1, SP3 and SP5) are named after the payload in kilograms and work with small robots and cobots. The compact SP design ensures that the workpiece is easily accessible, even in tight spaces. Without the requirement for electronics or air supply, the Gecko Gripper is a cost-effective, true plug-and-play solution. Integrates seamlessly with the robot of your choice.

Lagere operationele kosten, hogere ROI

Laat geen sporen achter op het glas, dus geen manuele reiniging vereist

Snellere, meer productieve oplossingen

Geen kabels of externe luchttoevoer vereist

Uitgebreide automatiseringsmogelijkheden

Kan zelfs geperforeerde werkstukken zoals printplaten, aluminium gaas of koppakkingen vastpakken

De voordelen van de Gecko Gripper

The Gecko Gripper offers automation without markings for flat, glossy and perforated workpieces and without the requirement for electricity or air supply. The Gecko Gripper is available in three sizes; SP1, SP3 and SP5 named after the load capacity of the gripper in kilograms, with the ability to lift a wide range of flat, smooth, glossy or perforated surfaces. Because the technology does not mark high-gloss surfaces, no cleaning is required in the production process, saving time and improving production. Like its bigger brother, the Gecko Gripper can even grip perforated workpieces such as printed circuit boards, aluminum mesh or head gaskets.

Compact, lichtgewicht en flexibel

The compact design ensures that the workpiece is easily accessible, even in tight spaces.

Beschikbaar voor een laadvermogen van 1 kg, 3 kg of 5 kg

The Gecko Gripper is available in three sizes; SP1, SP3 and SP5 named after the load capacity of the gripper in kilograms, with the ability to lift a wide range of flat, smooth, glossy or perforated surfaces.

Geen kabels of luchttoevoer vereist

Without the requirement for electronics or air supply, the Gecko Gripper is a cost-effective, true plug-and-play solution.

Weinig of geen programmering vereist

The gripper comes with pre-integrated software that is easy to install and program so that even employees without a technical background can install it.

Grijpertechnologie die geen markeringen achterlaat voor glanzende werkstukken zonder opeenvolgende reiniging

Our Gecko-inspired bonding technology provides precise gripper technology that leaves no marks, even for perforated objects such as printed circuit boards or for glossy surfaces

Krachtige grijpertechnologie voor geperforeerde werkstukken

The Gecko Gripper can even grip perforated workpieces such as printed circuit boards, aluminium mesh or head gaskets – expanding automation capabilities.

INTERESSE?

NEEM CONTACT OP MET ONS!

EEN OFFERTE AANVRAGEN

Toepassingen met Gecko Gripper

MATERIAALBEHANDELING

Gripper technology that leaves no markings for pick and place processes. Even objects that are perforated can be easily picked up.

MEER

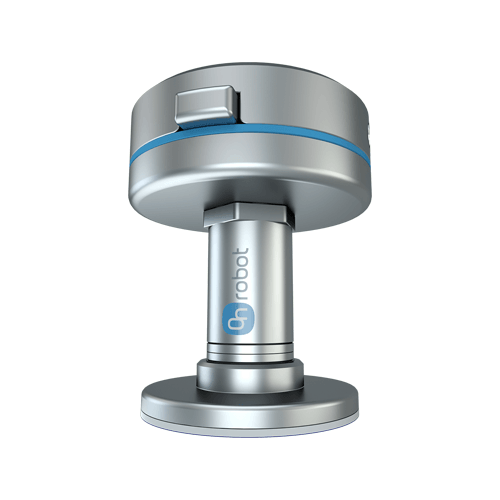

Compatibel met een breed gamma robotten

| Wilt u onze producten verkopen? Sluit uzelf aan bij ons partnernetwerk! |

Een partner worden |

OnRobot Product Brochure

OnRobot products open new possibilities for automating tasks that you never thought possible. Check out our product brochure to see how you can save cost and increase productivity with flexible automation tools